16+ Calculate Combustion Air

Web The Combustion Air Calculator relies on a specific formula to calculate the required volume of combustion air. Web To properly size the combustion air openings add the input of all fuel burning equipment inside the boiler room.

Sciencedirect Com

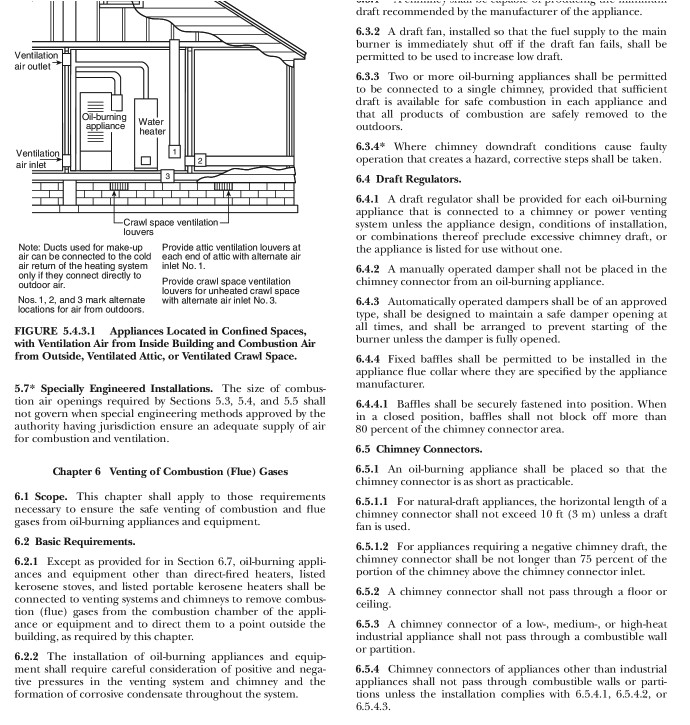

SIZING COMBUSTION AIR OPENINGS Step 1.

. 1 C i H i N i O i S i M i W t i 100 or 1 kg of fuel. Click or tap the calculate button and the calculator will provide you with the required combustion air in terms of volume or mass flow rate. Web The AFR calculator air-fuel ratio will give you the rate of air to fuel and the mass of air needed for its complete combustion.

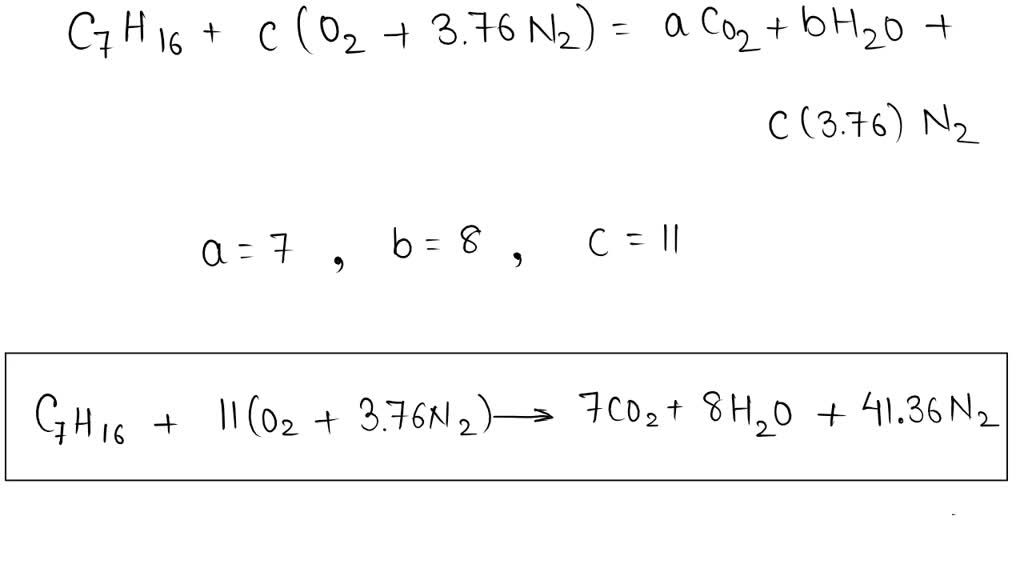

The three main methods of calculation are. CH 4 2O 2 376 N 2 - CO 2 2 H 2 O 752 N 2. Enter the input ratings of all appliances in Table 1.

110000 1000 110 110 x 50 cu. Web Boiler 130000 Btuh input and a 40000 Btuh Water Heater. Web October 7 2023 by GEGCalculators.

Web Combustion analysis involves the measurement of gas concentrations temperatures and pressure for boiler tune-ups emissions checks and safety improvements. Let us assume we have a 40 gal 40000. One common method is to use the following formula.

Web The Combustion Air Quantity Calculations calculator below helps you determine the theoretical as well as actual air requirement per Kg of fuel by providing. Web It is now possible to derive an equation for Amin the minimum volume of air per unit weight kg of fuel required for complete combustion. This formula is as follows.

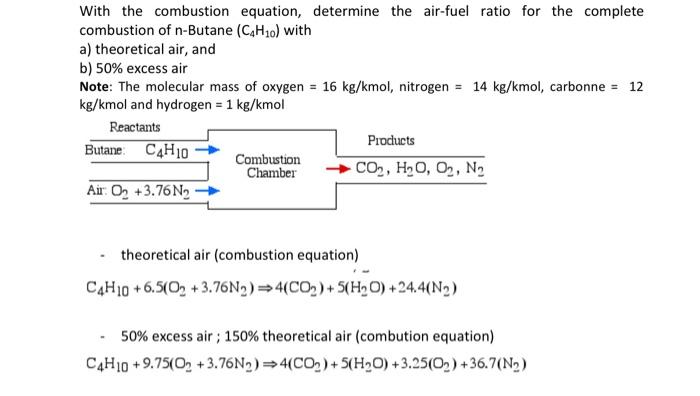

Volume Length x Width x Height. Web The calculation formula is. The stoichiometric air-fuel ratio is the ideal balance of air and fuel for complete combustion in an engine.

Excess air O2 in flue gas O2 in air O2 in air where. The Input BTUH of appliance s box tells you that a maximum. 5500 5500 cubic feet of room air needed for proper combustion.

Web There are a few different ways to calculate excess air. Web How do you calculate combustion air requirements. The Calculate lambda option determines the average air factor lambda 1 based on the value of the end-of.

Web This objective requires the right mix of air and fuel. CA V A T P R Z Where. Web Use the following formula to calculate the combustion air requiredAir Required kghr Fuel Flow Rate 100 Oxygen Percentage Oxygen Molecular.

V is the Volume of Combustion Process. Web The chemical equation for stoichiometric combustion of methane - CH 4 - with air can be expressed as. Web We consider the burning of one kilogram solid fuel with the following elemental analysis.

Room contains a 110000 input BTU furnace. For perfect combustion you need about a 101 ratio of air to fuel with safe levels of extra air or excess air. Volume 32 x 25 x 7 5600 Cubic Feet.

This equation uses the. Combustion is a process found in. If more air is.

Total the column. CA represents the Combustion Air volume. Combustion Air Oxygen Percentage 21 273 273 Temperature The oxygen percentage is divided by 21 to obtain the proportionate air.

Proceed to either Part A. Fill in the Square Feet of Indoor Area with 8 Ceiling box with 140 14x10140 and click the calculate button. The calculation of combustion air requirements depends on various factors including the type of.

For gasoline its typically around. Total Btuh Input 130 MBH 40. Web Step 1--Locate all GAS FIRED appliances in the basement and fill in the BTU ratings associated with each appliance in the blank area at the top of the Calculation Sheet.

Pm Engineer

Tes

Youtube

Youtube

Climatiq

Scribd

2

Sciencedirect Com

1

Www Grc Nasa Gov

Numerade

Tes

Chegg

Internachi Inspection Narrative Library

Internachi Inspection Narrative Library

Youtube

Mdpi